3 Essential Site Work Safety Principles

The health and well-being of your project team is paramount. But there are other benefits to adopting a no-excuses approach to safety protocols.

“Projects that prioritize safety will typically see increased productivity, reduced costs, a cleaner site, and an overall boost to the morale of the workers,” shares Horst Excavating’s Safety Officer, Matt Frank.

Site work has unique risks and safety procedures that everyone on site should know. This guide will help your team avoid mistakes that can lead to accidents. We’ll address:

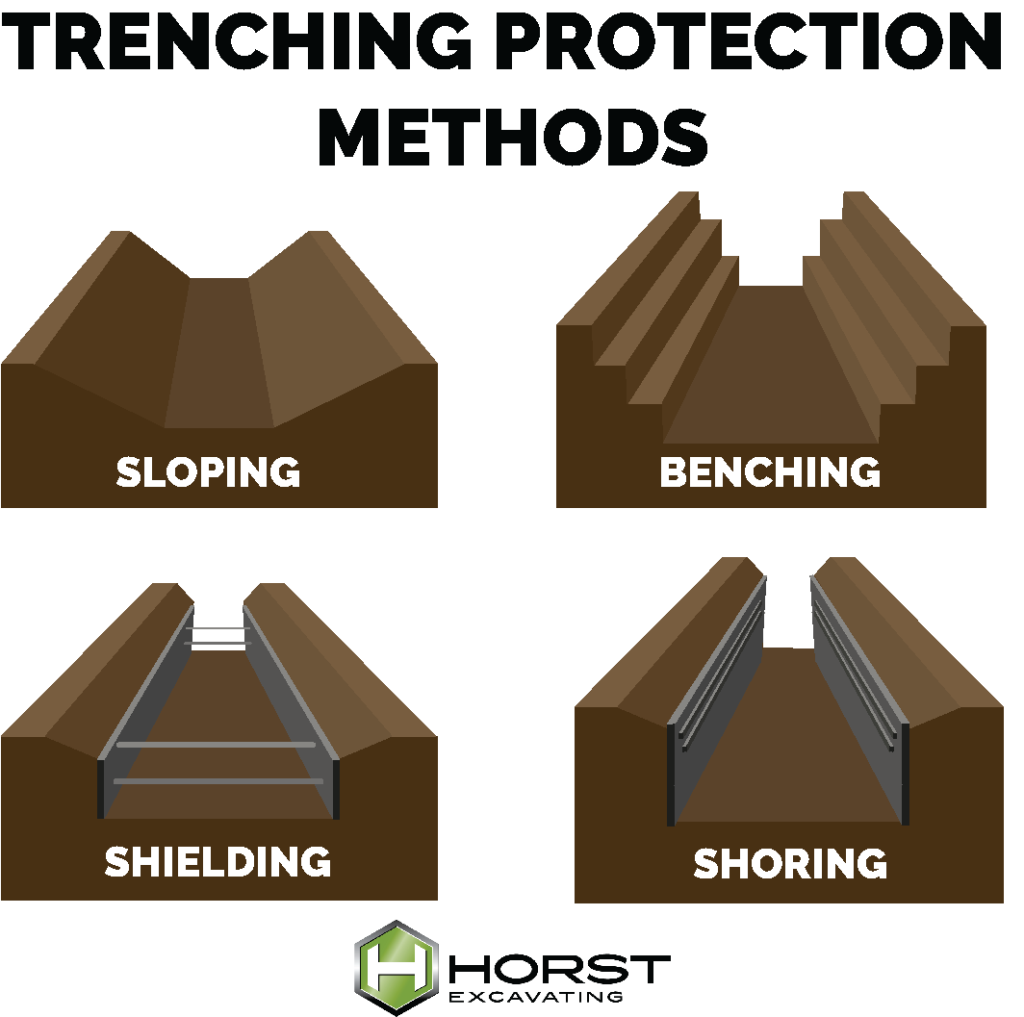

- Sloping, Benching, Shoring, and Shielding

- Utility Locating and Safe Digging Practices

- Equipment Operations, Maintenance, and Traffic Management

Disclaimer: This is not intended to be an all-encompassing safety plan. Each project has specific challenges. The best approach is to work with an experienced safety professional to ensure your specific needs are addressed.

1. Sloping, Benching, Shoring, and Shielding

Trench collapse hazards are a serious threat. Sloping, benching, shoring, and shielding are essential measures that prevent them.

Trench collapse hazards are a serious threat. Sloping, benching, shoring, and shielding are essential measures that prevent them.

These methods are required for trenches with a depth of five or more feet. However, they may be required in shallower trenches if the soil is unstable.

Sloping & Benching

Sloping is when the walls of a trench are cut to a slope pitched away from the bottom of the excavation, drastically reducing the likelihood and severity of cave-ins.

The exact approach varies with site characteristics such as environmental conditions, surcharged loads, and soil type. Soil is graded as Type A, B, and C. Type A soils, like clay, are the most stable and can support a steeper slope angle (¾ to 1). Less stable Type C soils, like sand and gravel, need a more gradual slope (1½ to 1).

Another similar approach is benching, which consists of a series of small, step-like levels leading out of the trench.

Shoring

Shoring is another cave-in prevention method that relies on a trench wall support system to keep dirt in place. These vertical supports are installed against the trench walls and are bolstered by perpendicular cross braces.

Shoring can come in handy when the soil stability is too poor for sloping, or if the trench is particularly deep.

Shielding

Other Trenching Essentials to Keep in Mind

There are a few other things you need to keep in mind throughout the process to maintain a safe environment while working in trenches and excavations.

- Continuously monitor dig zones for signs of shifting, settling, or instability. If you notice anything, address it quickly.

- Surface encumbrances need to be removed or supported. These include any obstacles on the ground near the trench that could impede construction, like trees, bushes, and utility poles.

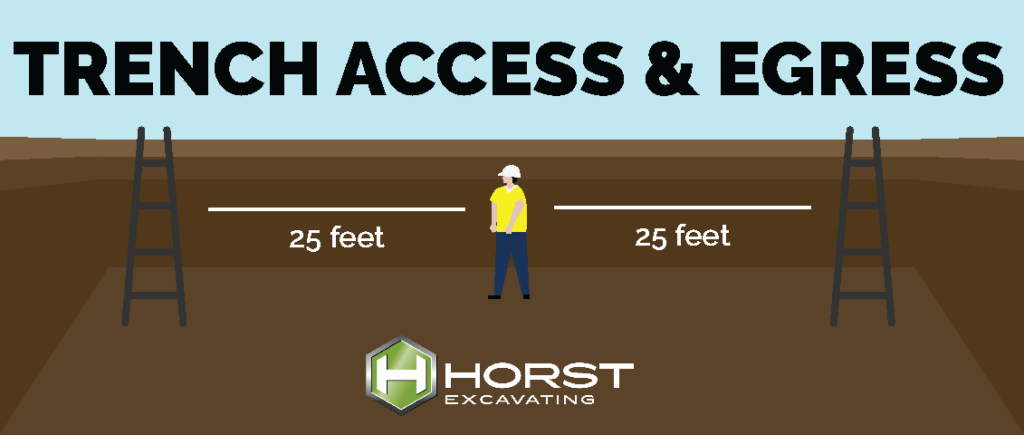

An entrance/exit (like a ladder, stairs, or ramp) is required for trenches 4 feet or greater in depth, and workers should never have to travel more than 25 feet to reach one.

- If workers are in excavations deeper than four feet and there is an oxygen-deficient or hazardous atmosphere, the team must test and monitor the air in the excavation. This can especially be an issue near sewer lines and landfills.

- If water accumulates in trenches, work must stop. Proper precautions must be taken if work continues.

Matt offers a concise and memorable way to ensure you’re following all trench safety procedures.

“It’s as simple as 1,2,3,4,5! 1 competent person must be on site at all times. Keep all spoil piles and equipment back at least 2 feet from the edge of a trench. When using a ladder, it must extend at least 3 feet out of the trench. All excavations greater than 4 feet in depth require a ladder. Lastly, any trench that’s greater than 5 feet in depth requires at least one form of protective system.”

2. Utility Locating and Safe Digging Practices

One way to do this is to contact utility companies and request markers for the location of lines on site. In some instances, utility locations may already be marked on the site plans. Ground-penetrating radar can also detect buried lines and their exact location.

Certain states and municipalities may have additional services that provide locations of underground utilities. In Pennsylvania, construction teams are required to call the Pennsylvania One Call System (811) for markings at least three days before digging with powered equipment.

Once utilities are mapped and marked, work must be conducted with care. Excavators should use non-destructive digging methods to minimize the chance of damage, like hydro-excavation or hand digging.

3. Equipment Operations, Maintenance, and Traffic Management

Machinery is vital to many site work projects, but this powerful equipment requires proper maintenance and operation to maintain safety.

The equipment owner and/or operator should regularly inspect for signs of wear or damage. They should also follow a regular maintenance schedule so oil is replaced, filters are changed, and moving parts stay lubricated.

At Horst, we maintain our own equipment fleet, so we’re invested in the machinery we bring on site. It’s in our best interest to make sure it’s in top working order.

“Regardless of the size of the equipment on site, it all deserves the same amount of respect in regards to safety,” shares Matt. “Heavy equipment and machines all carry the potential to cause one of the ‘Fatal Four’ hazards in construction. This being falls, struck by object, electrocutions, and caught-in/between incidents.”

Equipment operators must also work safely. These machines should only be used by trained professionals. Operators should follow guidelines for loading and unloading, traveling on uneven terrain, and working near obstructions.

“For operators, it is important that you always maintain at least three points of contact when entering or exiting the equipment to prevent falls,” shares Matt. “They need to be mindful of where their equipment is in relation to any powerlines and maintain the distances established by OSHA in order to prevent electrocutions.”

Those who are working around this equipment also need to work carefully. “Workers must always be aware of where the equipment around them is located. Stay out of blind spots and never assume that an equipment operator sees you to avoid being struck by equipment,” Matt informs. “It’s also important for workers to not place themselves in a tight spot where they can be caught in between moving equipment and a solid surface. For example, this could be a wall and a truck, or a trench box and the arm of an excavator.”

Training should also cover proper startup/shutdown procedures and emergency response plans.

Partner With Safe Site Work Contractors

Site work contractors work with unstable ground, essential utilities, and heavy equipment. In these environments, unsafe practices can cause a plethora of issues.

Working with a team dedicated to safety is key to avoiding poor outcomes. Your site work contractor should have the dedication and knowledge needed to work safely. That leaves you more time to focus on other aspects of the project, like driving it forward to the finish line.

At Horst Excavating, we believe that safety is more than just a word on our website or a 50-page document. It’s a commitment every employee makes to themself and their teammates. We provide them with the knowledge and resources they need to do their job safely, and we trust them with the responsibility to carry it out onto every job site.

Posted March 28, 2024

An entrance/exit (like a ladder, stairs, or ramp) is required for trenches 4 feet or greater in depth, and workers should never have to travel more than 25 feet to reach one.

An entrance/exit (like a ladder, stairs, or ramp) is required for trenches 4 feet or greater in depth, and workers should never have to travel more than 25 feet to reach one.