Excavating Technology is Evolving. Here’s How It’ll Impact Your Construction Project.

From the invention of the wheel to semi-autonomous excavators, the tools we create to help us build our environment are constantly evolving. In the hands of talented and experienced site work professionals, these advancements help us create better sites in less time.

In this blog, we’ll take a high-level look at the technological innovations in excavating and what they can contribute to a construction project.

Where We Began

For millennia, humans have been creating structures and altering our environment. The technology that we use to do so has evolved right alongside our civilizations.

The great ancient Egyptian and Roman structures we still admire utilized animal and manual labor. They also employed ramps, levers, pulleys, and cranes to move the giant building components that comprise these long-enduring structures. Various versions of these tools were used throughout the centuries to shape our world.

The Industrial & Technological Revolution

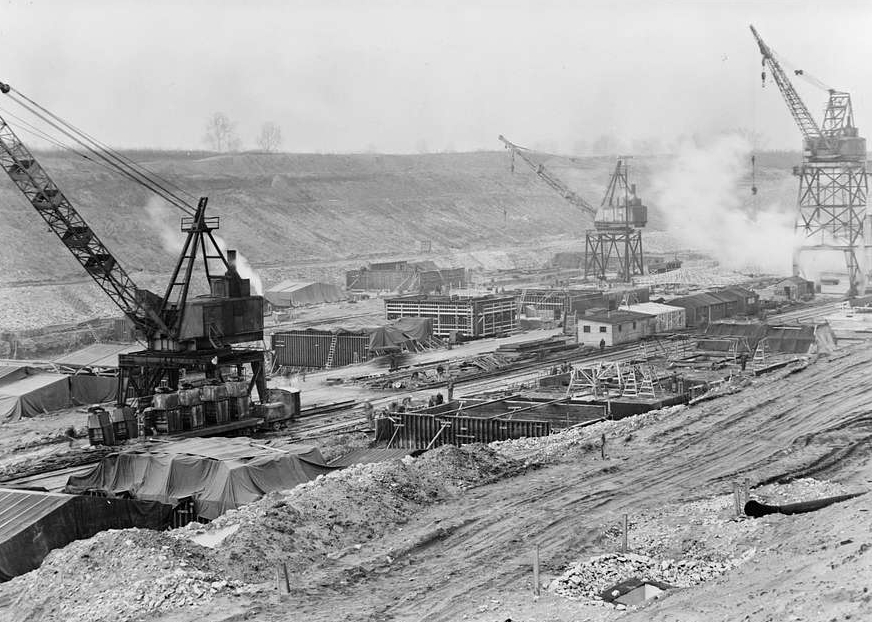

Image from the Library of Congress: https://www.loc.gov/resource/hhh.il0557.photos/?sp=57

With the advent of steam- and gas-powered engines, heavy equipment design erupted in the 19th century, driven mostly by the agricultural sector. By the 20th century, this technology was applied to the construction industry in the form of early versions of scrapers, bulldozers, rollers, excavators, dump trucks, and more.

Driven by a wave of development and public works, this technology was expanded and refined throughout the 1900s. As we entered into the 2000s, the focus shifted to making this equipment more efficient, compact, and equipped with accuracy-boosting technology.

Computers and Internet-of-things (IoT) devices of today help both in the field and the office. From GPS-enabled machines to computer-aided designs and site condition reports, technology is making the site work and construction process better for construction teams and owners alike.

Computer-Aided Design (CAD)

CAD tools, like InSite Software, have revolutionized the site work process, from project planning to on-the-field monitoring. At Horst Excavating, we use InSite to create detailed 3D models of a site by incorporating topographical data and project specifications. These models give us accurate and precise insight into all phases of the project.

The 3D models are then uploaded to our rover, which is used to localize the project site. It then helps us check grades, complete as-built surveys for utilities, calculate volumes, and assist with the coordination of 3D machine-controlled equipment.

GPS-Enabled Equipment

Before GPS-enabled construction equipment, people would use grading stakes to survey a site, and communicate to equipment operators how much cutting and filling was needed in a specific area. This process typically required crew members to stand by the grading stakes while large construction equipment operated around them. This process works well, but it’s not always the safest or most efficient method.

GPS technology makes accurate excavation easier and faster. Enabled on many new heavy equipment models, this technology provides real-time updates on the grade of the land, giving them insight into where and how much earth needs to be moved. Additionally, the equipment’s blades can be equipped with GPS to get right to the precise level detailed in the model.

In addition to GPS, modern equipment is outfitted with sophisticated sensors and control interfaces, allowing our talented operators to achieve unparalleled precision.

To learn more about how we use GPS in site work and excavating, check out this blog.

Remote Operations & Automation

We employ select remotely operated equipment like walk-behind rollers that are run by controllers just a few feet away. These compact yet powerful machines allow us to compact soil and pavement in tight or otherwise tricky spaces. By allowing operators to control the machine from a safe distance, the risk of accidents is reduced.

Unlike walk-behind rollers, there’s a newer crop of equipment that relies on remote operation from much further distances. Since the 2010s, manufacturers have explored remote operation for several other types of equipment, like excavators, wheel loaders, and more. This equipment can be operated in command stations located several miles from the equipment themselves. Time will tell if this technology is adopted industry-wide.

Looking Ahead

According to Common Ground Alliance’s 2022 Technology Report, plenty of advances are coming down the pike by the start of the next decade. Overall, they expect to see technology woven into nearly every site work task, enhancing accuracy and efficiency.

Electronic white-lining and supporting equipment may help to greatly reduce the risk and costs associated with excavating damage. Contractors would mark their dig site on satellite or drone imagery, and locators could then virtually review the site. During the excavating process, compatible equipment, perhaps through a screen in the cab, would have access to the white-lined layout. These machines could also feature sensors on their buckets that would alert operators if they’re too close to a buried line.

Other cutting-edge technology that currently exists and is continuously developing include:

- A small ground penetrating radar (GPR) that can be used above ground and even mounted to a drone.

- Semi-autonomous equipment that makes more accurate cuts easier, like Volvo’s Active Control.

- Equipment with sensors that continuously calculate payload weight to prevent underloading and overloading.

- 360-degree cameras on heavy machinery to help improve visibility.

- Equipment with improved fuel efficiency to cut both emissions and costs.

The Most Valuable Asset: People

While new technologies can enhance the excavating world, they’re only as effective as the people operating them. At Horst Excavating, our team of site work professionals marries good, old-fashioned experience and hard work with cutting-edge technology. This enables us to deliver the best results for our clients, partners, and team members.

Let’s talk about how we can help you on your next construction project.

Posted December 01, 2023